Essential for Modern Industries

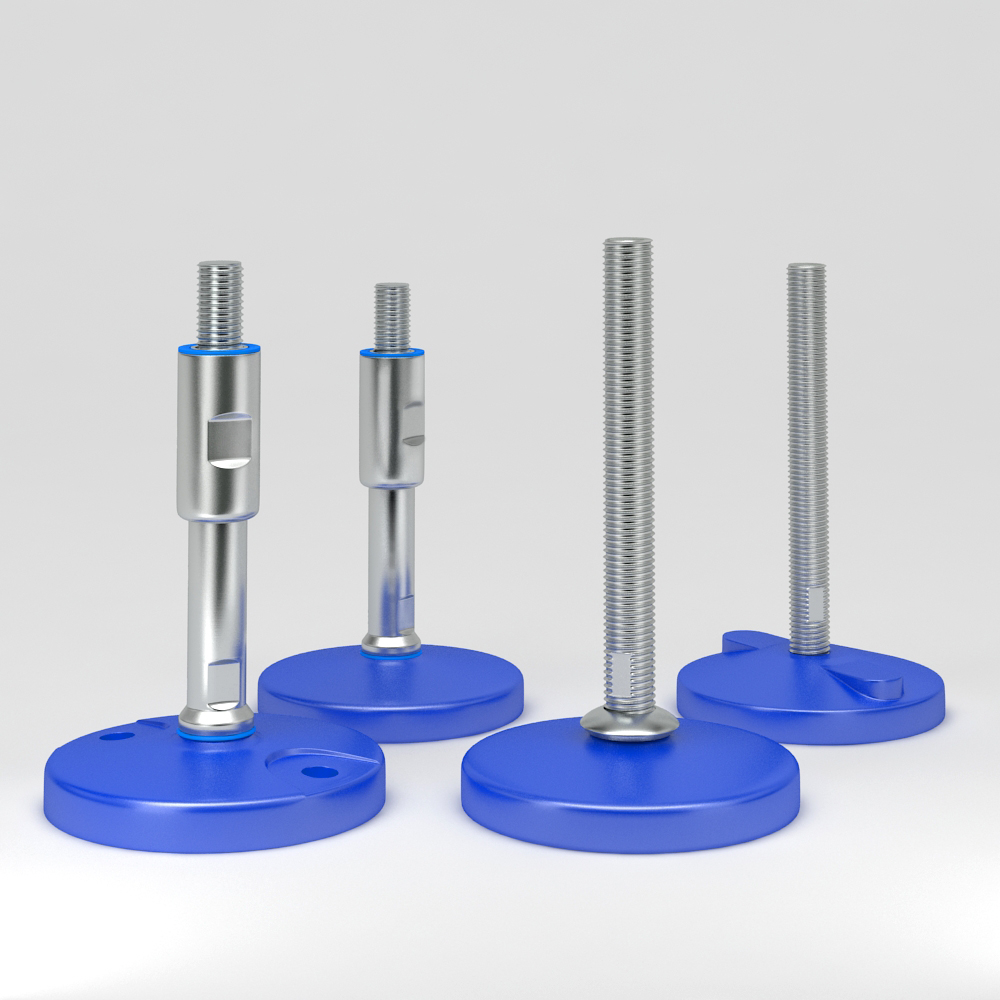

In today’s rapidly evolving industrial landscape, maintaining the optimal performance and longevity of machinery is paramount. One critical component that plays a pivotal role in this regard is the sanitary designed anti-vibration machine leveling feet. These innovative products not only enhance machinery stability but also ensure compliance with stringent hygiene standards across various sectors.

Understanding the Importance of Machine Leveling Feet

Machine leveling feet are essential components used to support and stabilize machinery. They provide a firm foundation, allowing for adjustments to ensure machines remain level on uneven surfaces. This stability is crucial for the efficient functioning of machines, reducing wear and tear, and preventing misalignments that could lead to operational failures.

The Role of Anti-Vibration Features

Vibration is a common challenge in industrial environments. It can cause significant damage to machinery, reduce precision, and increase noise levels. Anti-vibration machine leveling feet are designed to address these issues by absorbing and dampening vibrations. This feature enhances the machine’s performance, extends its lifespan, and improves safety by reducing the risk of machinery shifting or toppling over.

Why Choose Sanitary Designed Machine Leveling Feet?

In sectors such as food processing, pharmaceuticals, and biotechnology, maintaining a sterile environment is crucial. Sanitary designed machine leveling feet are specifically engineered to meet these high hygiene standards. Here’s why they are indispensable in such settings:

- Hygienic Materials: These leveling feet are typically made from stainless steel or other non-corrosive materials that are easy to clean and resist contamination. This ensures that they do not harbor bacteria or other pathogens that could compromise product safety.

- Smooth Surfaces and Crevice-Free Design: The design minimizes crevices and gaps where bacteria could accumulate. This is essential in maintaining cleanliness and adhering to industry regulations.

- Corrosion Resistance: Exposure to harsh cleaning chemicals and environments can lead to corrosion. Sanitary designed leveling feet are built to withstand these conditions, ensuring durability and reliability over time.

- Compliance with Industry Standards: Many industries are governed by strict standards and regulations regarding equipment hygiene. Sanitary designed leveling feet help businesses comply with these requirements, avoiding costly penalties and ensuring consumer safety.

Applications Across Various Industries

Food and Beverage Industry

In the food and beverage industry, maintaining cleanliness and hygiene is not just a priority—it’s a necessity. Equipment used in production lines must adhere to stringent sanitary standards to prevent contamination. Sanitary designed anti-vibration machine leveling feet play a crucial role in ensuring equipment stability and hygiene, thus safeguarding product quality and consumer health.

Pharmaceutical and Biotechnology Sectors

Pharmaceutical and biotechnology industries operate under some of the most rigorous hygiene standards. The equipment used in these fields must be impeccably clean to prevent any risk of contamination that could affect the integrity of pharmaceutical products. Sanitary machine leveling feet, with their easy-to-clean design and corrosion-resistant materials, are integral to maintaining the required standards of cleanliness.

Manufacturing and Heavy Machinery

In general manufacturing and heavy machinery applications, stability and durability are paramount. The anti-vibration properties of these leveling feet help reduce machine downtime and maintenance costs by minimizing the wear and tear caused by constant vibration.

Healthcare and Laboratory Environments

In healthcare and laboratory settings, precision and hygiene are crucial. Equipment stability is vital to ensure accurate results and prevent contamination. Sanitary designed leveling feet provide the necessary support and cleanliness to uphold these high standards.

Benefits of Using Anti-Vibration Machine Leveling Feet

- Enhanced Stability and Precision: By providing a stable base, these leveling feet ensure that machines operate with greater accuracy, which is particularly important in industries where precision is critical.

- Reduced Maintenance Costs: By minimizing the impact of vibrations, these feet reduce the wear and tear on machinery components, leading to lower maintenance costs and longer equipment life.

- Improved Safety: Stability reduces the risk of accidents caused by machinery movement, enhancing workplace safety.

- Compliance with Standards: Sanitary designs ensure that equipment meets industry regulations, avoiding legal issues and enhancing brand reputation.

Key Features to Look For

When selecting sanitary designed anti-vibration machine leveling feet, consider the following features:

- Material Quality: Look for high-grade stainless steel or similar materials known for their durability and hygiene.

- Load Capacity: Ensure the feet can support the weight of your machinery without compromising stability.

- Adjustability: Opt for leveling feet that allow for easy adjustments to accommodate uneven surfaces.

- Vibration Damping: Check the effectiveness of the anti-vibration features to ensure optimal performance.

- Easy Installation and Maintenance: Choose designs that are simple to install and maintain, reducing downtime and labor costs.

Sanitary Designed Anti-Vibration Machine Leveling Feet

Sanitary designed anti-vibration machine leveling feet are an essential component in modern industrial operations. They provide stability, enhance performance, and ensure compliance with hygiene standards, making them invaluable in various sectors. By investing in these innovative products, businesses can improve operational efficiency, ensure product quality, and maintain a safe and compliant workplace environment.

Essential for Modern Industries

For industries committed to excellence and safety, integrating sanitary designed anti-vibration machine leveling feet into their operations is not just a smart choice—it’s a necessary one. These components exemplify the perfect blend of functionality and hygiene, meeting the demands of today’s stringent industrial standards.