In the realm of engineering and manufacturing, the selection of bearings is a pivotal decision that impacts the efficiency, longevity, and performance of machinery. Choosing the right bearings is not merely a technical requirement but a strategic imperative. This article delves into the critical importance of strategic bearing selection and how it can significantly enhance engineering outcomes.

The Role of Bearings in Engineering

Bearings are fundamental components in machinery, facilitating smooth and efficient motion by reducing friction between moving parts. They are crucial in a wide array of applications, from automotive engines to industrial machinery and aerospace systems. The correct selection of bearings ensures that these machines operate reliably, with minimal downtime and maintenance costs.

Impact on Efficiency and Performance

Selecting the right bearings directly influences the efficiency of a machine. High-quality bearings reduce energy consumption by minimizing friction, leading to smoother operation and less wear and tear on components. This not only extends the lifespan of the machinery but also enhances its performance, ensuring that it runs at optimal speeds and capacities.

Moreover, strategically selected bearings can handle higher loads and speeds, which is essential for high-performance applications. By choosing bearings designed to meet specific operational requirements, engineers can ensure that machinery performs consistently under varying conditions.

Longevity and Maintenance

One of the most significant benefits of strategic bearing selection is the extension of machinery lifespan. Bearings that are tailored to the specific needs of an application are less likely to fail prematurely. This reduces the frequency of maintenance and the associated costs, as well as minimizing the risk of unexpected breakdowns that can halt production and lead to significant financial losses.

Properly selected bearings also contribute to improved safety. Bearings that are designed for specific conditions are less likely to overheat or wear out, reducing the risk of accidents and ensuring a safer working environment.

Economic Considerations

From an economic perspective, the strategic selection of bearings is a cost-effective measure. While high-quality, application-specific bearings may have a higher upfront cost, they offer substantial savings over time. Reduced maintenance costs, lower energy consumption, and prolonged machinery life all contribute to a more economical operation.

Additionally, investing in the right bearings can lead to increased productivity. Machines that operate efficiently and with fewer interruptions can produce more output, contributing to higher revenue and a better return on investment.

Environmental Impact

In today’s engineering landscape, environmental considerations are increasingly important. The right bearings can help reduce the environmental footprint of machinery. By improving energy efficiency and reducing the need for frequent replacements, strategically selected bearings contribute to more sustainable operations.

Energy-efficient bearings reduce the overall energy consumption of machinery, which can lead to lower greenhouse gas emissions. Furthermore, the extended lifespan of bearings means fewer resources are required for manufacturing replacements, thereby conserving raw materials and reducing waste.

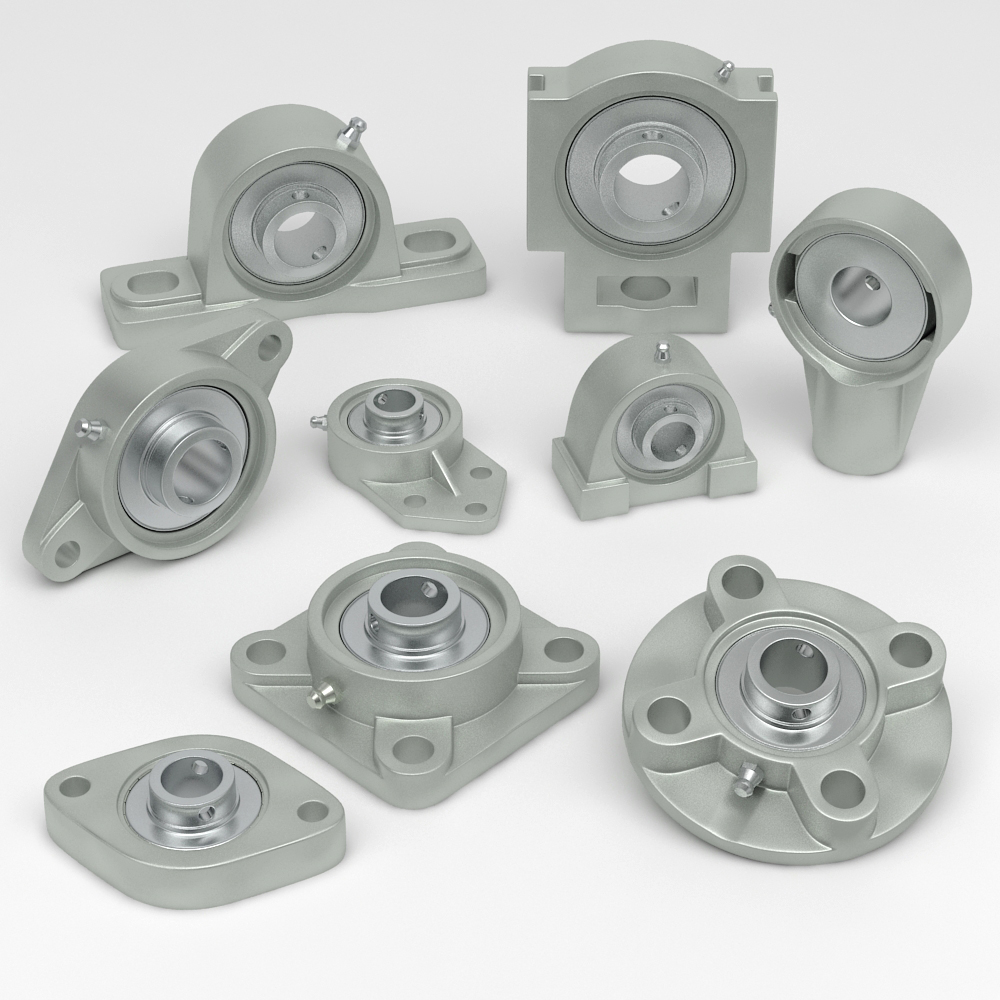

Mounted ball bearing house units

Strategic bearing selection is an engineering imperative that encompasses efficiency, performance, longevity, maintenance, economic benefits, and environmental impact. By prioritizing the selection of the right bearings, engineers can significantly enhance the operational capabilities of machinery, leading to improved productivity, safety, and sustainability.

In summary, the right bearings are more than just components—they are critical assets that play a crucial role in the success of engineering projects. Making informed, strategic decisions in bearing selection can lead to long-term benefits that far outweigh the initial investment.