A Comprehensive Guide

In the world of industrial equipment, ensuring stability and minimizing vibration are crucial for efficient operations and product longevity. One often-overlooked component that plays a vital role in achieving these goals is the machine leveling foot. Specifically, sanitary designed vibration damping machine leveling feet are essential for industries that require stringent hygiene standards, such as food processing, pharmaceuticals, and biotechnology. This article delves into the importance of these components, their features, and how they can benefit your operations.

Understanding Machine Leveling Feet

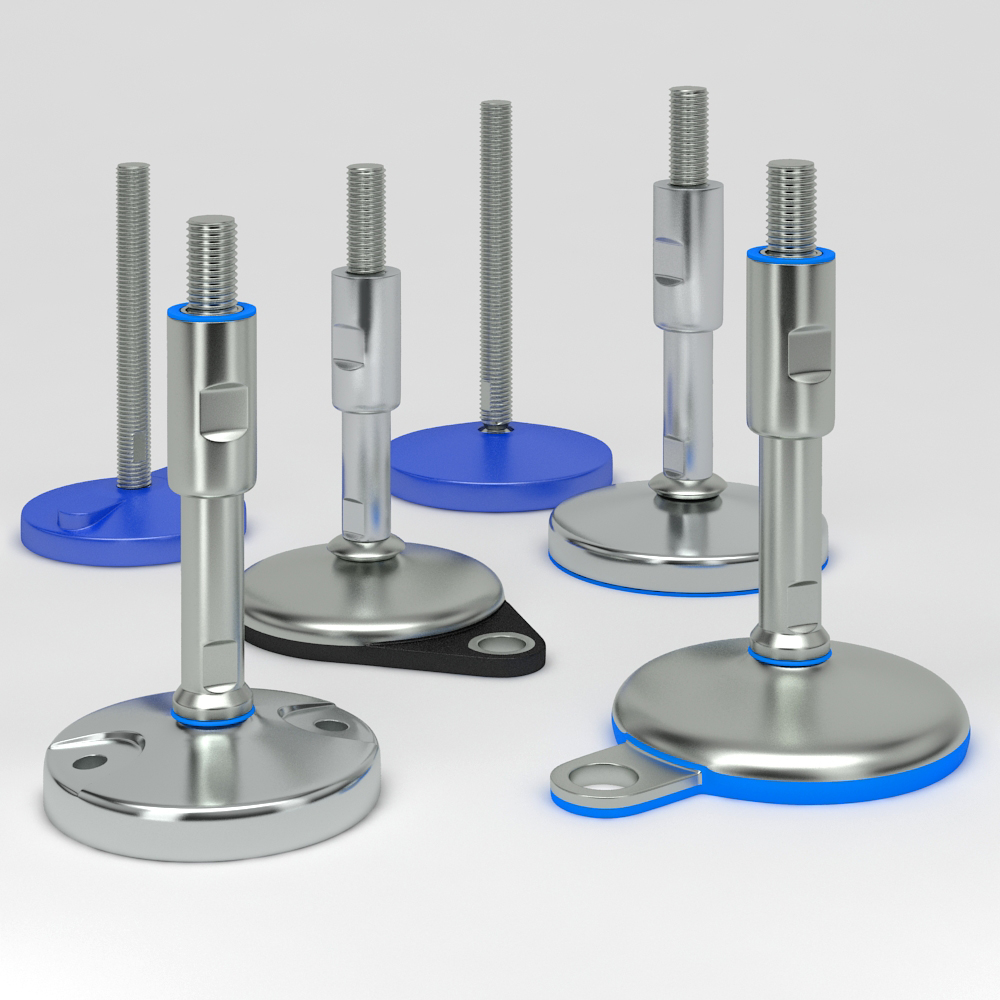

Machine leveling feet are devices used to stabilize machinery and equipment by providing a level base and minimizing vibration. These components are adjustable, allowing for precise leveling on uneven surfaces, which is critical for maintaining the accuracy and efficiency of machines. In industries where hygiene is paramount, sanitary design features are incorporated into these feet to ensure they meet health and safety standards.

The Importance of Sanitary Design

Sanitary design is crucial in industries that handle consumable goods. Equipment in these sectors must be easy to clean and resistant to contamination to prevent any compromise in product quality. Sanitary designed machine leveling feet are made from materials such as stainless steel, which is resistant to corrosion and easy to clean. The smooth surfaces and minimal crevices of these feet prevent the accumulation of dirt and bacteria, ensuring compliance with hygiene regulations.

Key Features of Sanitary Designed Vibration Damping Machine Leveling Feet

- Corrosion Resistance: These feet are typically made from stainless steel, which offers excellent resistance to corrosion. This property is crucial in environments where exposure to moisture, chemicals, or extreme temperatures is common.

- Hygienic Surfaces: The design of sanitary leveling feet includes smooth surfaces with minimal seams and joints. This feature reduces the risk of bacterial growth and makes cleaning easier, thus ensuring compliance with sanitary standards.

- Vibration Damping: Vibration damping is a critical feature that protects sensitive machinery from excessive vibration, which can lead to wear and tear or operational inaccuracies. These feet often incorporate elastomeric pads or other damping materials to absorb vibrations effectively.

- Adjustability: To achieve optimal machine performance, leveling feet are adjustable, allowing precise alignment and leveling of equipment on uneven floors.

- Load Capacity: Designed to support heavy machinery, these feet are robust and capable of handling significant loads without compromising stability.

- Ease of Installation: Sanitary designed leveling feet are typically easy to install and require minimal maintenance, reducing downtime and associated costs.

Benefits of Using Sanitary Designed Vibration Damping Machine Leveling Feet

Improved Equipment Stability

By providing a stable base, these leveling feet help prevent machinery from shifting during operation. This stability is essential for maintaining the accuracy and precision of machines, especially in industries where even minor deviations can lead to significant quality issues.

Enhanced Vibration Control

Vibration damping is critical for protecting sensitive components and ensuring the longevity of machinery. By absorbing and minimizing vibrations, these leveling feet help reduce wear and tear, lower noise levels, and enhance overall operational efficiency.

Compliance with Hygiene Standards

In industries with strict hygiene regulations, such as food and pharmaceuticals, using sanitary designed components is essential. These leveling feet are designed to meet such standards, ensuring that equipment does not become a source of contamination.

Cost-Effective Maintenance

The durability and corrosion resistance of these leveling feet lead to reduced maintenance costs. Their ability to maintain equipment stability also minimizes the likelihood of breakdowns, further reducing operational costs.

Applications of Sanitary Designed Vibration Damping Machine Leveling Feet

Food Processing

In food processing plants, hygiene is of utmost importance. Equipment must be easy to clean and resistant to bacterial growth. Sanitary leveling feet ensure that machinery remains stable and free from contamination, helping maintain high standards of food safety.

Pharmaceutical Manufacturing

Pharmaceutical environments require stringent cleanliness and precision. Sanitary designed leveling feet help maintain the stability and accuracy of sensitive equipment, ensuring consistent product quality and compliance with regulatory standards.

Biotechnology

Biotechnology facilities often deal with sensitive biological materials that require precise handling. Sanitary leveling feet provide the necessary stability and hygiene to support these operations, ensuring optimal performance and safety.

Selecting the Right Leveling Feet for Your Needs

When choosing sanitary designed vibration damping machine leveling feet, several factors should be considered:

- Load Capacity: Ensure that the leveling feet can support the weight of your equipment without compromising stability.

- Material: Opt for materials like stainless steel that offer corrosion resistance and easy cleaning.

- Vibration Damping: Evaluate the damping capabilities of the leveling feet to ensure they meet your operational requirements.

- Adjustability: Consider the range of adjustability needed to achieve precise leveling on uneven surfaces.

- Compliance: Verify that the leveling feet meet industry-specific hygiene standards and regulations.

Sanitary Designed Vibration Damping Machine Leveling Feet: A Comprehensive Guide

Sanitary designed vibration damping machine leveling feet are an essential component for industries that require stability, precision, and hygiene. Their robust design, vibration damping capabilities, and compliance with sanitary standards make them ideal for food processing, pharmaceuticals, and biotechnology sectors. By investing in high-quality leveling feet, businesses can enhance equipment performance, reduce maintenance costs, and ensure compliance with stringent hygiene regulations. Choosing the right leveling feet for your specific needs will contribute significantly to the efficiency and success of your operations.